أرسل لنا رسالة

what is calcination of gypsum mining

Calcination parameters on phosphogypsum waste recycling

2020年9月30日 Calcination of PG was made in a stationary kiln in three different residence times (1 h, 2 h, and 5 h) and temperatures (120 °C, 150 °C, and 200 °C). To the calcination, 1.5 kg of PG powder was spread into a metallic tray in a thin layer by each calcination

Mechanism of calcination modification of phosphogypsum

2020年5月20日 The results show that the calcination pretreatment of PG reduced the adverse effects of impurities in PG and changed the gypsum phase to prepare SSCs with

Calcination parameters on phosphogypsum waste recycling

2020年9月1日 The calcination at low temperatures transforms phosphogypsum (PG) waste in a material with binder properties. This study evaluated two parameters of PG

Carbon footprint analysis of calcined gypsum production

2018年3月10日 The results of the environmental assessment showed for FGD gypsum as the raw material a carbon footprint of 105.3 kg CO 2 /t of calcined gypsum, which was

Influence of the Calcination Temperature of Synthetic

2020年11月3日 The stone assesses the influence of the calcination temperature of synthetic gypsum binder on the binding properties of innovative gypsum pastes, as well

Calcination Definition, Examples, Process,

2023年6月14日 Calcination, in simple words, can be described as a process of heating some solid material or a substance in a controlled environment. Usually, in the process, the temperature is also regulated.

Gypsum Calcining 911 Metallurgist

2019年4月6日 Gypsum Calcining Gypsum is the crystalline chemical compound CaSO42H2O. A close chemical relation and frequently occurring with Gypsum is Anhydrite which is CaSO4. Gypsun has wide

Gypsum Calcination Innogyps

Gypsum Calcination Calcination is the practice of dehydrating gypsum into plaster or stucco through a batch or continuous process which includes heating the gypsum to evaporate

Gypsum Definition, Uses,Facts Britannica

2023年5月12日 gypsum, common sulfate mineral of great commercial importance, composed of hydrated calcium sulfate (CaSO42H2O). In well-developed crystals the

A Study of Calcination of Gypsum Wallboard The NAFI Blog

The approach taken in this work incorporated small- and full-scale testing to accomplish several goals: 1) develop an objective method for measuring the calcination depth of

Mechanism of calcination modification of phosphogypsum

2020年5月20日 The properties of PG change after calcination. On the one hand, the gypsum phase changed significantly. Two mechanisms of the dehydration of the gypsum, which main component of PG-O, were identified. The compressive strength of filling body mixed by HCM and the addition of 0–160% tailings (HFM) can meet various mining

Calcination parameters on phosphogypsum waste recycling

2020年9月1日 With the best calcination temperature of 800 °C, gypsum plaster showed a relatively quick setting and maximum strength with a compact microstructure and low hydration degree due to the large

11.16 Gypsum Manufacturing US EPA

2015年9月10日 11.16 Gypsum Manufacturing 11.16.1 Process Description1-2 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral. Raw gypsum ore is processed into a variety of products such as a portland cement additive, Calcination occurs at approximately 120 to 150°C (250 to 300°F), and 0.908 megagrams

Lithium Production Processes ScienceDirect

2015年1月1日 Kalenowski and Runke 59 mixed gypsum and lime (at 1:2 mass ratio) with amblygonite (8.46% Li 2 O) for calcination at 950 °C within 2 h and then leached the calcine produced with water at a liquid–solid mass ratio of 5:1

Influence of the Calcination Temperature of Synthetic

2020年11月3日 The calcination process of gypsum binder was carried out at four different temperatures ranging from 170 to 190 °C. The specimens for testing were prepared on the basis of the obtained raw material with a constant water to gypsum ratio of w/g = 0.75. It was noted that the calcination temperature influenced the setting time of the gypsum.

[PDF] Influence of the Calcination Temperature of

2020年11月3日 The stone assesses the influence of the calcination temperature of synthetic gypsum binder on the binding properties of innovative gypsum pastes, as well as on masonry and plastering mortars. The calcination process of gypsum binder was carried out at four different temperatures ranging from 170 to 190 °C. The specimens for testing

(PDF) Calcination ResearchGate

2021年1月1日 Abstract and Figures. Mineral calcination is responsible for approximately 5% of global anthropogenic carbon dioxide (CO2) emissions every year. Providing this service without adding CO2 to the

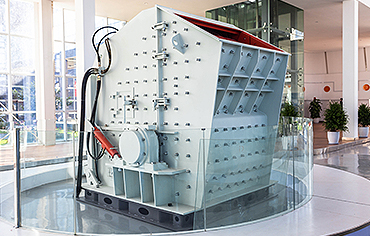

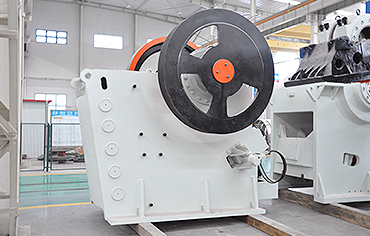

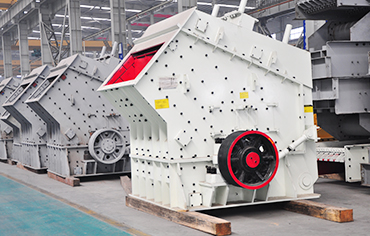

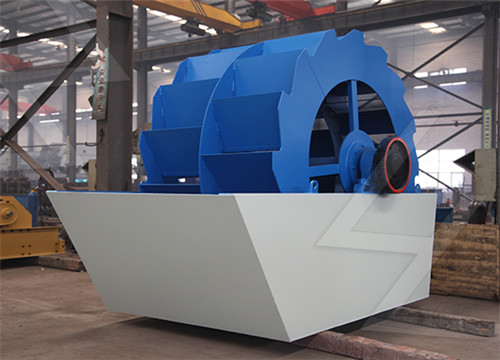

The Most Valuable Things You Need to Know about Gypsum

2023年4月23日 The production process of gypsum powder The gypsum powder production line is usually divided into gypsum mining, crushing, grinding, and calcination processes according to technical requirements.This is an on-site video of a gypsum production line and shows the entire process of gypsum powder.. 1. Gypsum mining process The gypsum is

Gypsum Calcination Innogyps

The calcination is controlled by a thermocouple within the stucco bed that changes the feed to maintain a constant temperature, just like a full sized industrial calciner. Calcination temperature can be set at approximately 135-180℃ and can be tuned to minimize residual gypsum and soluble anhydrite production and maximize hemihydrate production.

what is calcination of gypsum mining

what is calcination of gypsum mining defamiliethielsbe. Gypsum is widely used, a common such as industrial materials, construction materials, model making, additives and paint filler etc calcination of gypsum is a common way in the gypsum processing process, the process is generally as follows : Gypsum raw . الحصول على

Mechanism of calcination modification of phosphogypsum

2020年5月20日 The properties of PG change after calcination. On the one hand, the gypsum phase changed significantly. Two mechanisms of the dehydration of the gypsum, which main component of PG-O, were identified. The compressive strength of filling body mixed by HCM and the addition of 0–160% tailings (HFM) can meet various mining

Calcination parameters on phosphogypsum waste recycling

2020年9月1日 Bumanis et al. [23] compared the properties of PG without or with slacked lime at calcination temperatures of 100 • C, 120 • C, 140 • C, 160 • C, and 180 • C, and the result showed that

11.16 Gypsum Manufacturing US EPA

2015年9月10日 11.16.1 Process Description1-2 Gypsum is calcium sulfate dihydrate (CaSO42H2O), a white or gray naturally occurringmineral. Raw gypsum ore is processed into a variety of products such as a portland cement additive,soil conditioner, industrial and building plasters, and gypsum wallboard.

(PDF) Calcination ResearchGate

2021年1月1日 Calcination Authors: Nils Haneklaus Abstract and Figures Mineral calcination is responsible for approximately 5% of global anthropogenic carbon dioxide (CO2) emissions every year. Providing...

Lithium Production Processes ScienceDirect

2015年1月1日 Kalenowski and Runke 59 mixed gypsum and lime (at 1:2 mass ratio) with amblygonite (8.46% Li 2 O) for calcination at 950 °C within 2 h and then leached the calcine produced with water at a liquid–solid mass ratio of 5:1

[PDF] Influence of the Calcination Temperature of

2020年11月3日 The stone assesses the influence of the calcination temperature of synthetic gypsum binder on the binding properties of innovative gypsum pastes, as well as on masonry and plastering mortars. The calcination process of gypsum binder was carried out at four different temperatures ranging from 170 to 190 °C.

The Most Valuable Things You Need to Know about Gypsum

2023年4月23日 The production process of gypsum powder The gypsum powder production line is usually divided into gypsum mining, crushing, grinding, and calcination processes according to technical requirements.This is an on-site video of a gypsum production line and shows the entire process of gypsum powder.. 1. Gypsum mining process The gypsum is

Gypsum Calcination Innogyps

Gypsum Calcination Calcination is the practice of dehydrating gypsum into plaster or stucco through a batch or continuous process which includes heating the gypsum to evaporate the crystalline water. Typically, free water is removed in an initial process at approximately 45℃ and crystalline bound water is removed in a second process at 120-180℃.

Gypsum Mining Processing Equipment Flow Chart

1 Gypsum is commonly associated with rock salt and sulfur deposits. It is processed and used as prefabricated wallboard or as industrial or building plaster, used in cement manufacture, agriculture and other uses. Gypsum Mining. IMAR 7 th Edition. Most of the world’s gypsum is produced by surface-mining operations.

Methodology for the free allocation of emission

2021年7月19日 “Drying or calcination of gypsum or production of plaster boards and other gypsum products, where combustion units with a total rated thermal input exceeding 20 MW are operated.” Activities of European gypsum installations, represented by EUROGYPSUM, can potentially fall under the following NACE Rev. 1.1/ PRODCOM codes: